AP and Other Projects of Paul Wussow

HOn3 Pickle Tub Car

A work in progress with HOn3 drawings, photos and models by Paul Wussow, inspired by the late Jim Vail’s articles and supportive e-mails.

Page link (Click here)

Progress and work parts for help evaluating progress and my work towards AP Cars Is below for a number of projects.

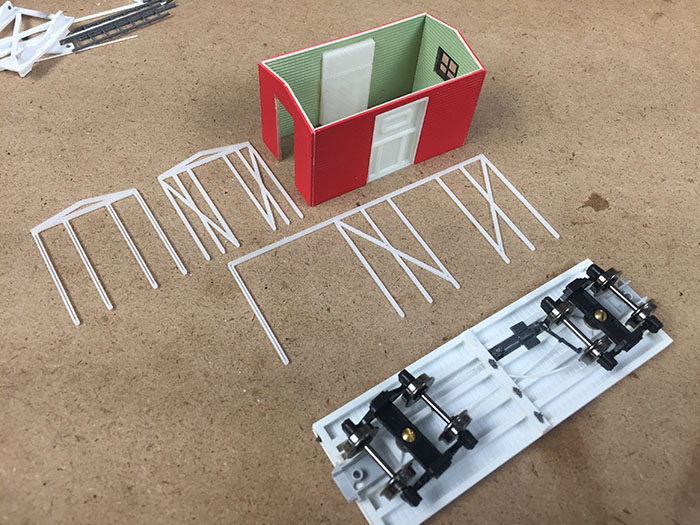

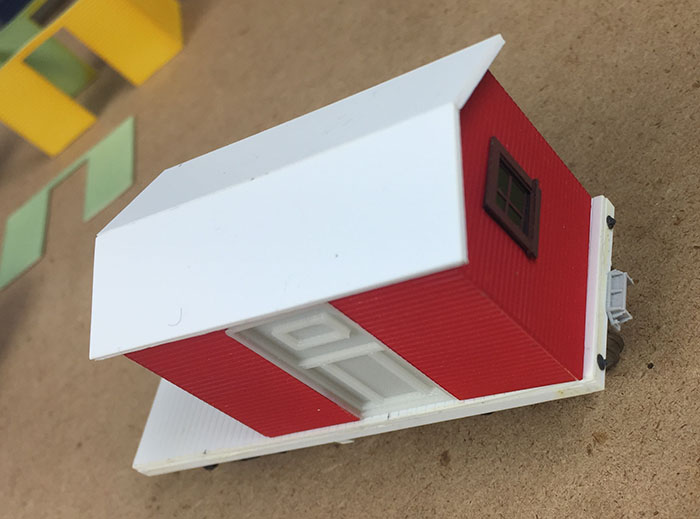

Work Caboose in HO and HOn3

More details on main page (Click Here)

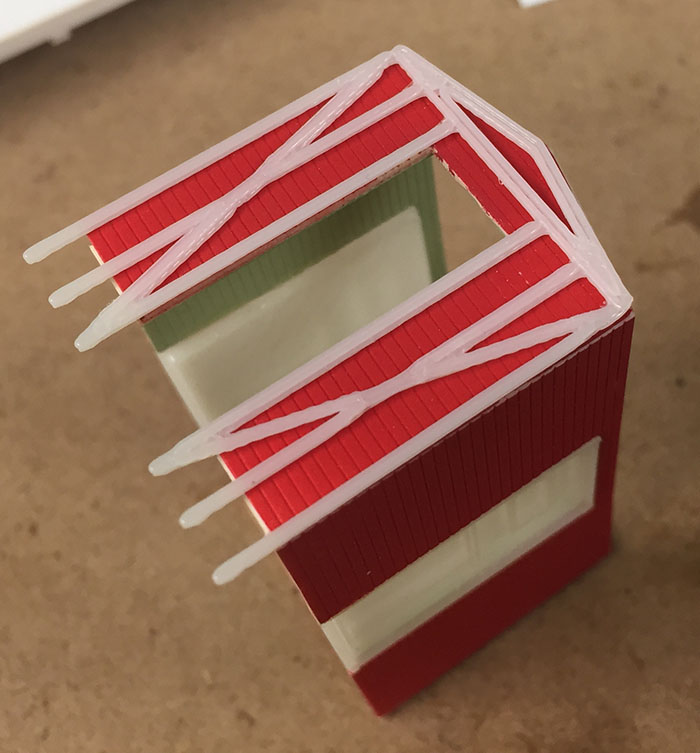

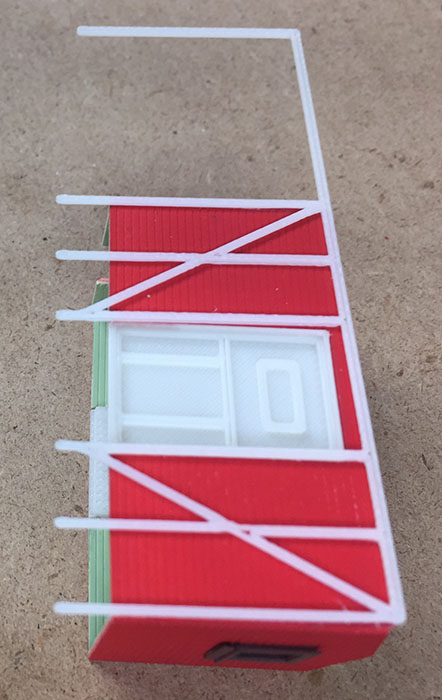

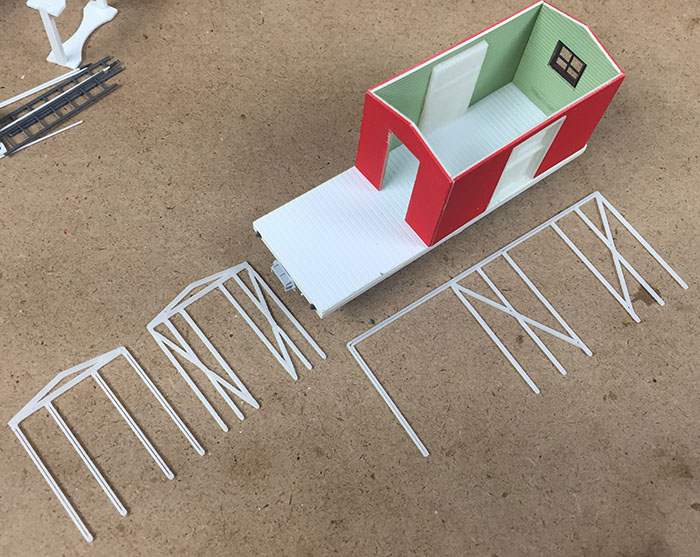

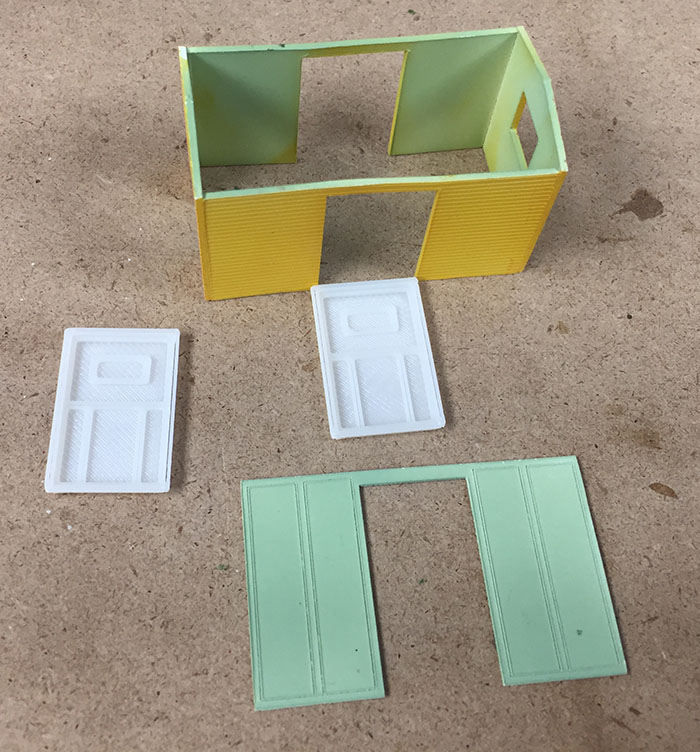

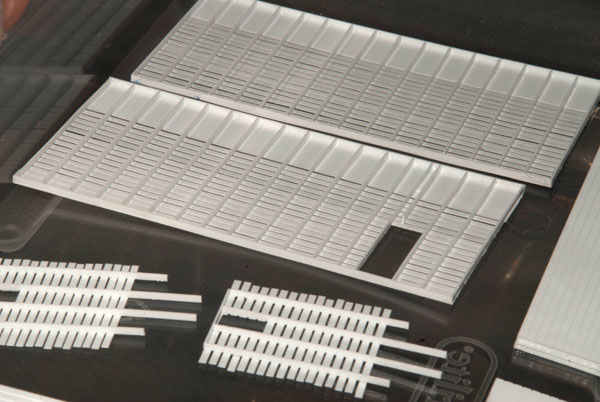

The Photos below show external frames these were printed as cutting on the laser melted the thin material causing warping.

The frames are made to fit around the car body and the frame.

The frames are made to fit around the car body and the frame.

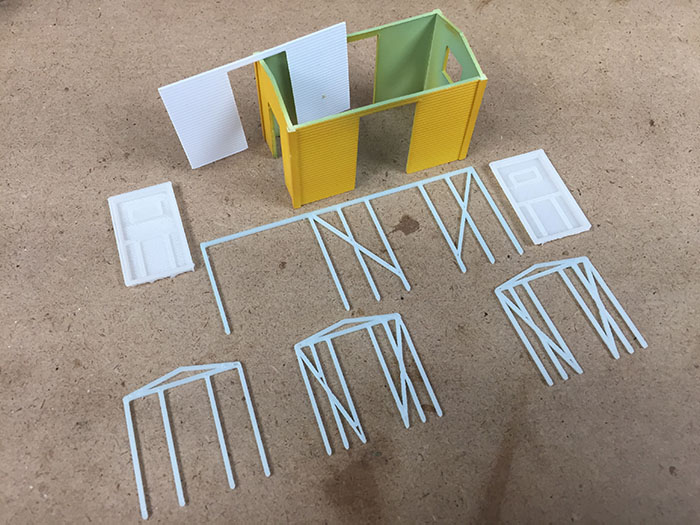

End Frames left to right are for the open area on the caboose and the next 2 to the left are cross braced for the body of the caboose.

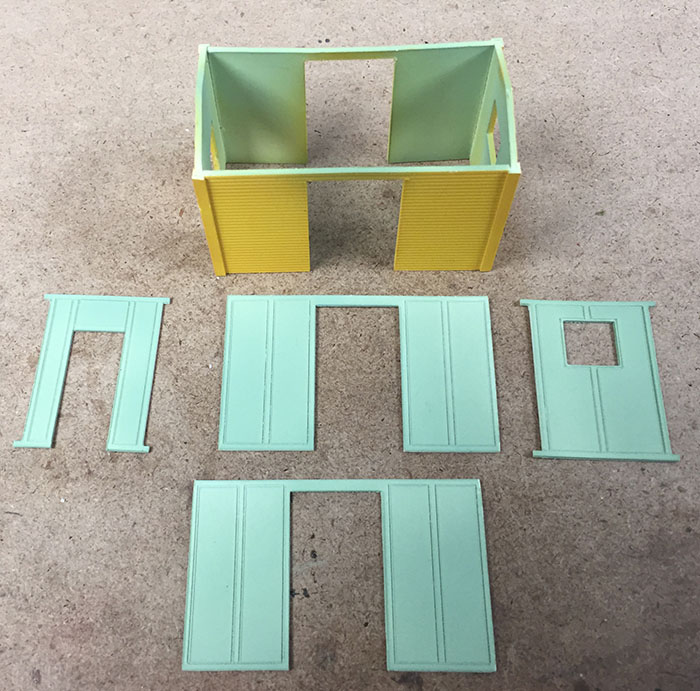

End Frames left to right are for the open area on the caboose and the next 2 to the left are cross braced for the body of the caboose. HO Scale interior and door

HO Scale interior and door

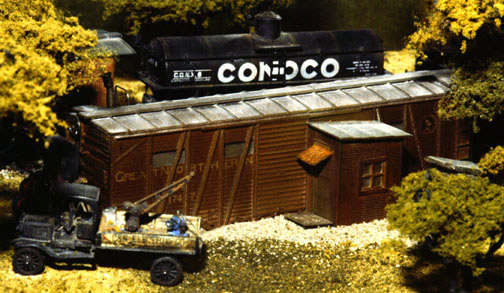

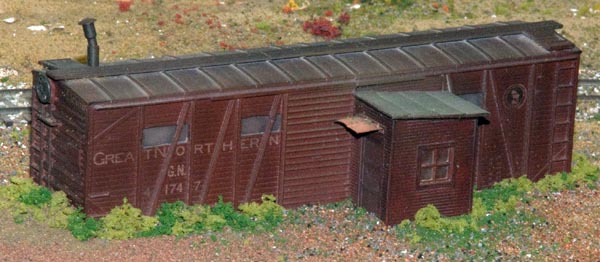

Logging Caboose

Details on Main Page (Click Here)

Detailed Kits in HO

Detailed structures

This started as a Woodland Scenics Machine Shop that I detailed and illuminated. Photographs of this finished model recieved and Honorable mention and award from Woodland Scenics. The photos have also been shown in the Chicago Photographic Socity and won awards in Division and regional meets.

The forge is lit with a LED that can be brightened when in use. The room lighting is done with surface mounted LEDs on the extra frame below the roof. There is a welder on the outside using an arc welder also lit by LEDs and animated to look like sparks of a stick welder.

The forge is lit with a LED that can be brightened when in use. The room lighting is done with surface mounted LEDs on the extra frame below the roof. There is a welder on the outside using an arc welder also lit by LEDs and animated to look like sparks of a stick welder.

Kit-Along project Main Page (Click Here)

This Atlas Tower has interior details including racks, and a washroom on the lower level and desks and work areas on the upper floor. Lights in different rooms allow for animation at night.

This Atlas Tower has interior details including racks, and a washroom on the lower level and desks and work areas on the upper floor. Lights in different rooms allow for animation at night.

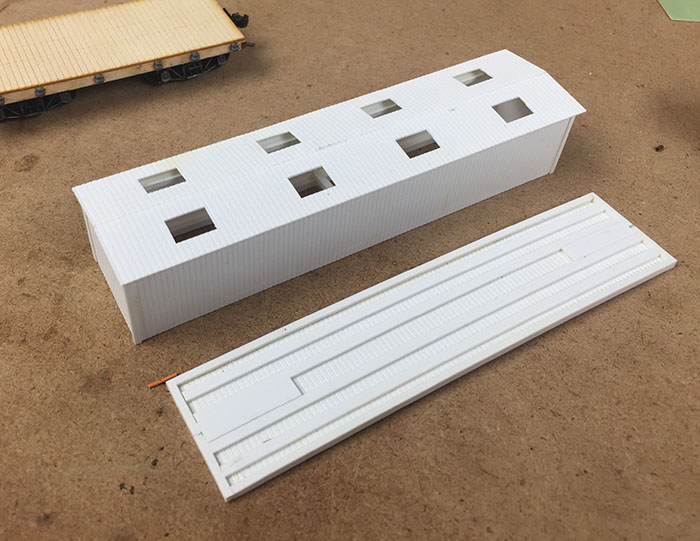

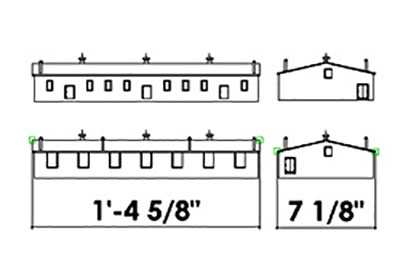

Laser Cut Walls for Starks Potato Warehouse

Main Page (Click Here)  South East end

South East end

Part of our club measuring up article published in 2012 at the South West end of the building.

Early Drawing in Vectorworks for a shortened HO version of the structure.

Laser etching of plywood with a negative image of the stonework allows the stone and concrete structure to be modeled and with painting taking on the correct appearance.

Laser etching of plywood with a negative image of the stonework allows the stone and concrete structure to be modeled and with painting taking on the correct appearance.

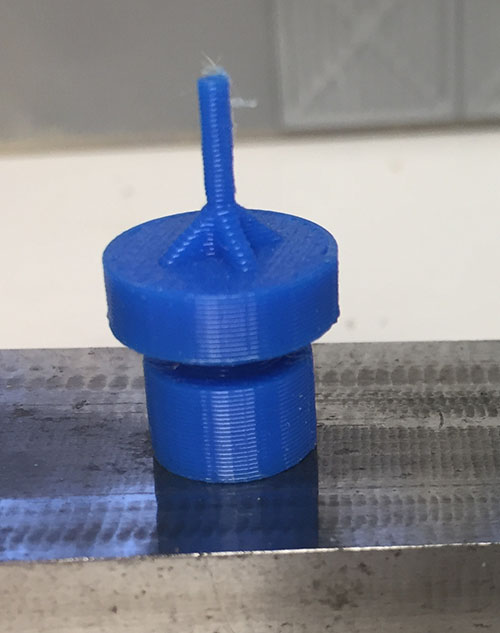

Roof Vents 3D Printed from my drawings

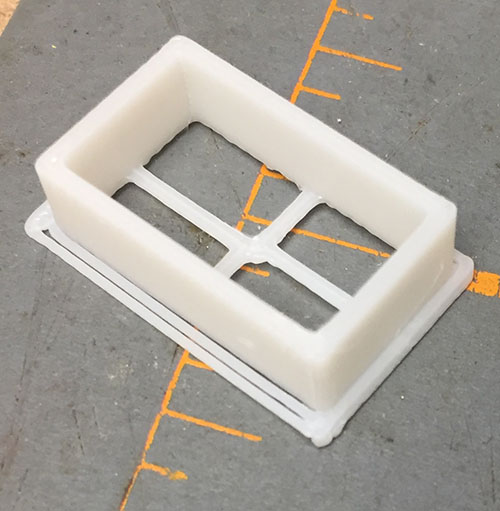

2 foot thick spacing for the windows matching the prototype walls with windows and frames. 3D Printed from drawings made after measurements at the site.

Woodboro WI Project

Main Pages (Click Here)

Warehouse

Prototype structure on site in Woodboro WI

Prototype structure on site in Woodboro WI

Model on a photo demo module.

General Store

One of many photos that covers the store from the late 1960s up to today. There is also documentation of the store in the book.

The First 100 Years of Woodboro.

Details on main Woodboro Pages (Click Here)

Black Jack's Bar (Click Here)

Scratch built Corn Crib details on main page

(Click Here)

Other work, 24' Work Caboose & Logger cabins

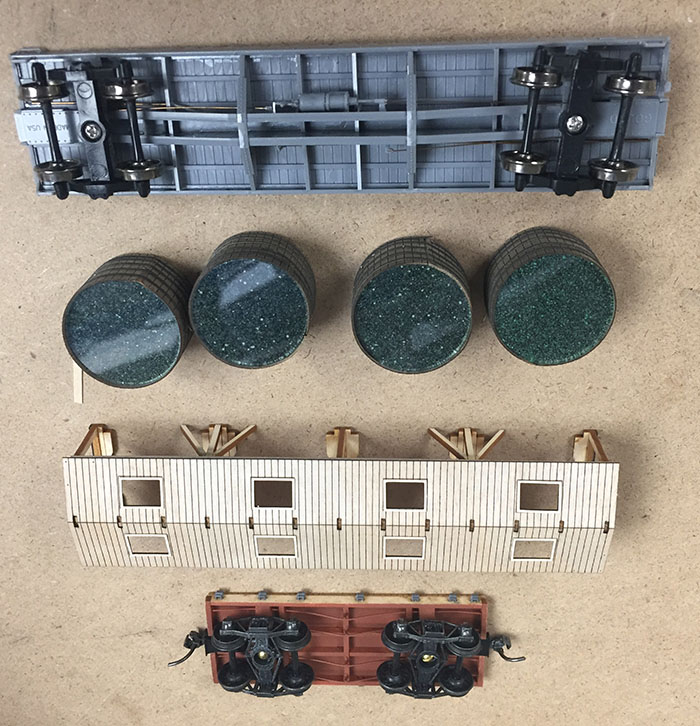

24' Work caboose

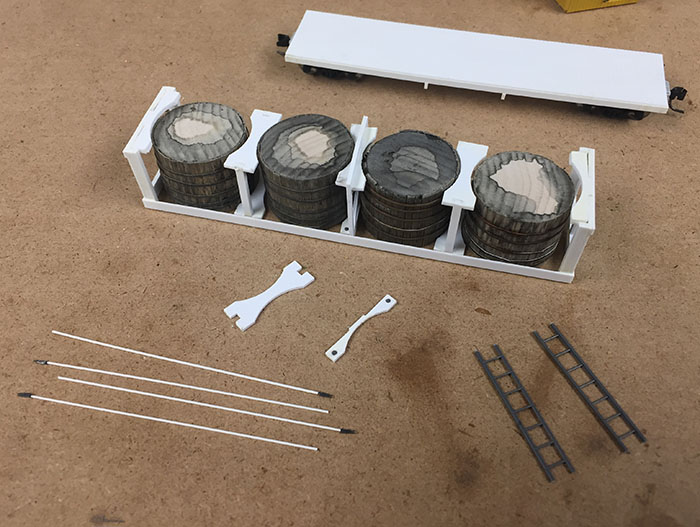

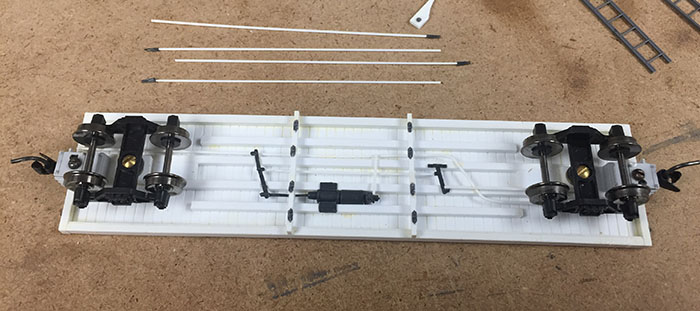

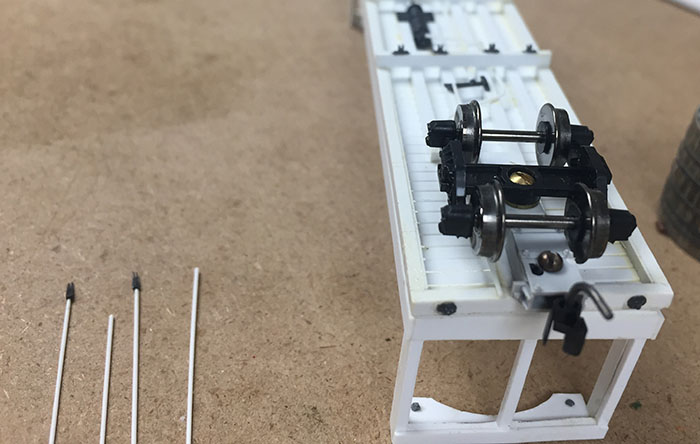

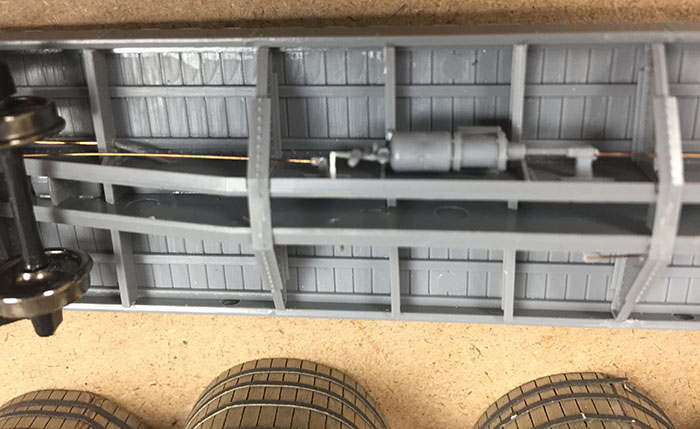

First steps working on the frame

First steps working on the frame

Truss Rods did not fit the holes so I replaced them with 30 gauge wire.

Here is the frame airbrushed with red oxide primer.

Here is the frame airbrushed with red oxide primer.

Logger's cabins

Painted roofing and smoke stacks on the roof placed on the roof.

First steps build the cabins less widows

First steps build the cabins less widows

Acrylic paint over alcohol stains with peeled paint FXs following FOS Scale Models instructions.

Acrylic paint over alcohol stains with peeled paint FXs following FOS Scale Models instructions.

3 cabins with windows and doors.

Notice the sub roofing, in some cases the tabs are tight as the size of the buildings have changed with painting and peeled paint. Care must be taken with the corners as the precut material is a little long and will force the roof up. Careful cutting or sanding of the corners and the door frames will help the sub roof fit snug to the cabin.

Notice the sub roofing, in some cases the tabs are tight as the size of the buildings have changed with painting and peeled paint. Care must be taken with the corners as the precut material is a little long and will force the roof up. Careful cutting or sanding of the corners and the door frames will help the sub roof fit snug to the cabin.

Updated 11/08/19

Join us in the “Greatest Hobby” as a member of the TLMRC.